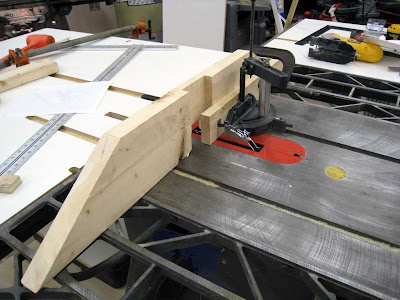

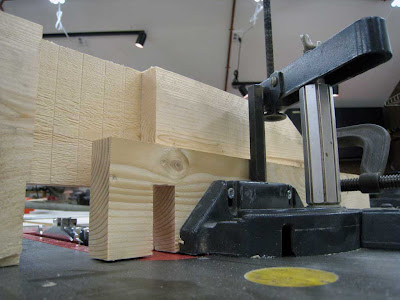

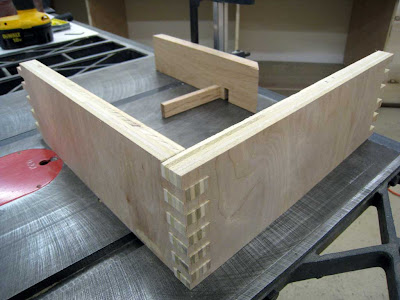

Made a few mistakes on the first box jig. The key is to make sure the dado, the pin, and the space between them is EXACTLY the same. During the first attempt I gave a light sanding to the pin to get it to fit. That made it so the joint was to tight to fit together, and the front and side of the corner ended up at different heights. So, unlike the picture below, the 2 pieces wouldn't have gone together (without a ton of force), and the piece on the right would be shifted down by a 16th of an inch or so.

Made a few mistakes on the first box jig. The key is to make sure the dado, the pin, and the space between them is EXACTLY the same. During the first attempt I gave a light sanding to the pin to get it to fit. That made it so the joint was to tight to fit together, and the front and side of the corner ended up at different heights. So, unlike the picture below, the 2 pieces wouldn't have gone together (without a ton of force), and the piece on the right would be shifted down by a 16th of an inch or so.

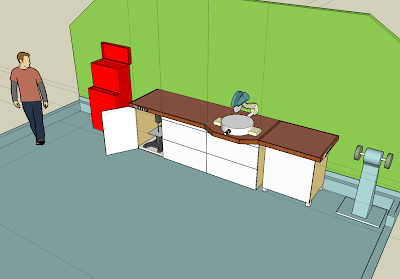

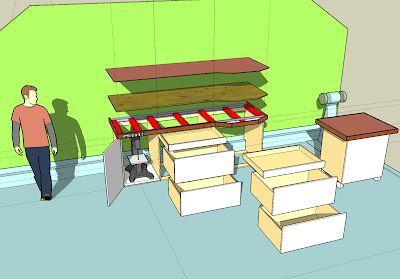

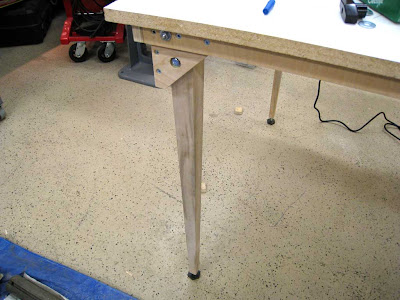

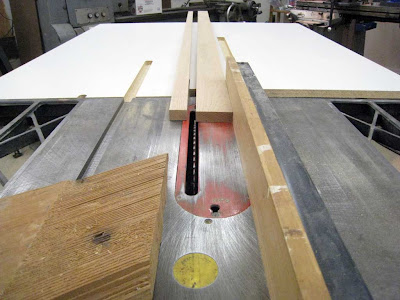

Masonite top and flush mounted oak trim.

Masonite top and flush mounted oak trim.

Ripped a couple of 3" strips of oak, bevel cut them to fit, and rounded the edges with the router.

Flush trimmed the masonite to the existing top instead of trying to cut it to fit.

Flush trimmed the masonite to the existing top instead of trying to cut it to fit. The Box of screws on the left was $4.19 at HomeDepot. The 7 pounds of screws on the right were $18.43 at Hiawatha Fasteners.

The Box of screws on the left was $4.19 at HomeDepot. The 7 pounds of screws on the right were $18.43 at Hiawatha Fasteners.